Pattern Imprinted Concrete Repair and Restoration

PolyBound Home Improvements will restore and repair your imprinted concrete driveway, path or patio to bring your home exterior back to life.

Specialist Imprinted Concrete Cleaning and Restoration.

In some cases, if left untreated and not maintained as well as it should be, the concrete itself can become exposed and this can lead to crumbling of the surface or parts of the pattern becoming chipped or scuffed.

PolyBound Home Improvements can restore the colour and pattern of your imprinted concrete to make it look as good as new with our professional three-step restoration process.

New Legislation Calls for Permeable Driveways

VubaMac: Flood Resistant Paving

NEW! Moisture Tolerant Premium Resin

Why choose Imprinted Concrete?

High pressure cleaning

Cracks and minor imperfections repaired

Once the surface is prepped and free of all loose dirt, weeds and stones, we can then get to work on assessing the quality of the imprinted concrete. Small cracks are repaired and any imperfections to the pattern of the concrete are rectified.

Restoring the colour and finish

Now that the pattern of your imprinted concrete surface has been restored, all minor cracks have been filled and your contraction joints have been resealed the next step is to select the correct colour pigment to reapply the colour. This is mixed with a durable sealant to not only restore, but to also protect the surface of the imprinted concrete from future fading or damage from frost.

How long will it last?

As with any outside surface, it’s important to make sure that you maintain the finish of your newly restored imprinted concrete driveway by keeping on top of regular maintenance. A regularly used drive, path or patio should be resealed every 2-3 years.

Our service is mess-free, friendly and reliable.

What is Imprinted Concrete?

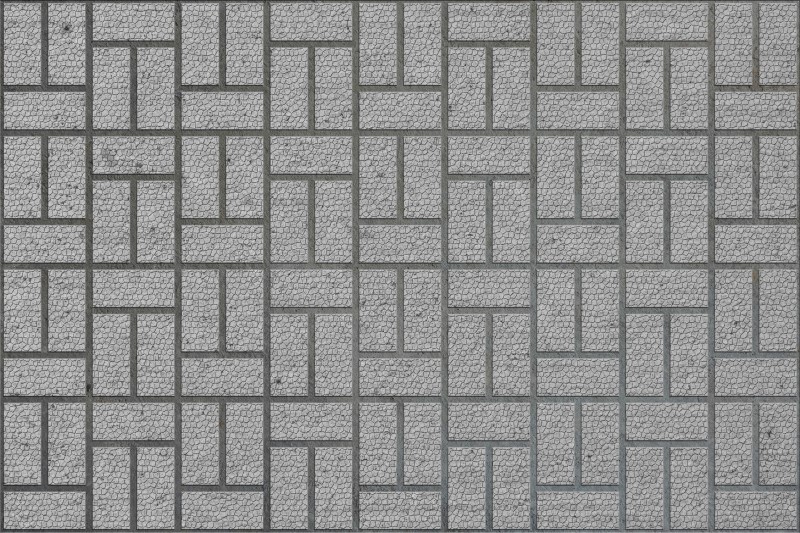

Imprinted concrete uses pattern mats to leave a block paving pattern on the top layer of the concrete. Rigid mats are placed into the concrete to create old English cobblestone patterns, herringbone designs and much more. The concrete is then treated with a colour surface hardener to achieve the desired look.

Once the pattern is applied and the concrete has hardened, contraction joints are cut into the concrete at areas of high stress to allow crack control, to reduce the likelihood of cracking across the whole of the surface. The joints should be filled with silicone to stop weeds growing and any build up of dirt, stones and rubbish.

Once this is complete, a solvent-based acrylic sealant is applied to aid the durability of the finished imprinted concrete surface. This should be reapplied every 3-5 years to ensure a long-lasting finish.

5 Star Reviews

5 Star Reviews